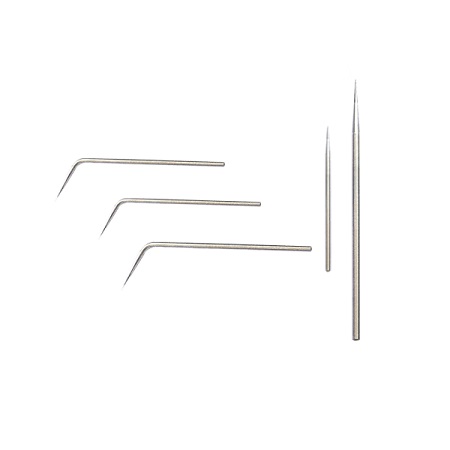

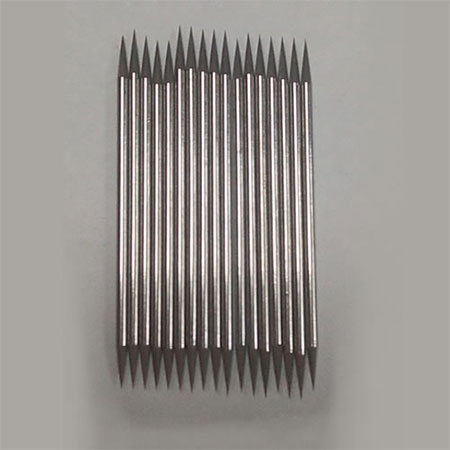

Probe Card Needles

Tungsten is the most common material of cemented carbide. Compared with other metals, it has stronger hardness, ductility, and is easy to process.

Among all pure metals, tungsten has the highest melting point. Compared with carbon, tungsten can maintain a solid state at a higher temperature, and tungsten has the lowest thermal expansion coefficient, with low thermal expansion coefficient, high melting point, and high tensile strength. strength.

Usually tungsten is also widely used, the most common being used as a durable metal in the construction industry such as metal processing and mining. Tungsten is a metal material with high temperature resistance. Since tungsten can be drawn into a wire-like shape, tungsten is also widely used and often used as electrodes, such as filaments, electrodes, thermocouples or probe needles, etc., but tungsten itself exists The problem of brittleness and low plasticity greatly reduces its life span during use.

The tip of the rhenium-tungsten probe is processed by a special process. The needle cone has high precision, high strength and elasticity. The product is more wear-resistant, more corrosion-resistant, and the surface is relatively smooth, and its brightness can reach The similarity is a mirror surface.

Rhenium-tungsten probes are the most widely used of all types of probes, and the scope of use of rhenium-tungsten probe cards has gradually increased. Rhenium-tungsten probes are used to reduce the brittleness of tungsten and improve its plasticity.

In addition, rhenium-tungsten has a very high melting point, so it is often used in aviation and high-temperature environments, such as electronic heating and welding.

Beryllium copper is a copper alloy with beryllium as the main alloying element. It is the best elastic material in copper alloys. It has high strength, high elasticity, high conductivity, high temperature resistance, corrosion resistance, strong fatigue, wear resistance, Cold-resistant, easy to process, and the best hardness and strength of all copper alloys; most suitable for long-life, high-temperature, high-current switch parts. It is an age-hardening material and is a micro switch, precision connector, and various The material of choice for precision shrapnel such as high-grade terminals and relays.

Beryllium copper is an age-hardening material with the highest strength among copper alloys. It is used in long-life terminals, micro switches, etc. The strength and wear resistance of beryllium copper are better than the physical properties of chromium-zirconium-copper alloys.

The tools made of beryllium copper are very hard and will not produce sparks when hitting the steel surface. Because beryllium has high flexural rigidity, thermal stability, thermal conductivity, and low density, they are all made Aviation-related materials are also used in missiles, space vehicles and satellites.

P7-Palladium alloy probes are commonly used test media for wafer testing. The direct contact between the probes and the tested pads transmits electrical signals to the tester to determine the quality of the chip circuit.

Under the implementation of the material of the cantilever probe and the contact resistance of the solder pad, the contact resistance of the material becomes larger quickly compared with the tungsten needle and the tungsten rhenium needle when the needle is tested at high temperature; while the beryllium copper needle is at high temperature. The performance is relatively stable.

P7-Palladium Alloy have higher melting points, which inhibits diffusion formation of intermetallic compounds.

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español Nederlandse

Nederlandse العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia বাঙ্গালী

বাঙ্গালী Türk

Türk 繁體中文

繁體中文